Simulating ammonia release in the working environment using CONTAM software: When technology helps to see invisible risks

Ammonia (NH3) is a familiar chemical compound, widely used in many industries such as fertilizer production, food processing, refrigeration industry, chemicals, etc. Although it plays an important role in production, due to having characteristics like rapid evaporation, strong dispersion and high toxicity, ammonia is considered one of the chemicals that pose many potential risks to workers’ health if not strictly managed and controlled in the workplace.

Under normal conditions, NH3 exists as a colorless gas with a distinct, pungent odor, easily noticeable when released into the environment. However, at concentrations of only 20–50 ppm, it can irritate the eyes, nose and respiratory tract. If the concentration reaches 500 ppm or more, this gas can cause serious damage and even death with only short-term exposure. In particular, NH3 gas is easy to react quickly with water vapor in the air, forming suspended aerosol particles, prolonging the residence time and increasing the level of danger for exposed people.

In fact, there have been many serious incidents involving ammonia. Typical examples include the NH3 gas leak in Ho Chi Minh City in 2017, which forced the evacuation of more than a thousand residents, or the gas tanker explosion in India in 2015, which caused great loss of life and property. These accidents are clear reminders of the need to improve the capacity to prevent and respond to chemical incidents, especially in industrial production environments.

Confronting such reality, a research team from the Vietnam National Institute of Occupational Safety and Health (VNNIOSH) has simulated the dispersion of NH3 gas using CONTAM software. The simulation results have provided important information about the path, spread level and residence time of toxic gas in the factory. This is a useful scientific basis for developing chemical incident response scenarios, contributing to protecting the safety of workers and improving the response capacity of enterprises.

Incident simulation using CONTAM: When technology helps “see the invisible”

To support enterprises in assessing the risk of NH3 gas leakage, the research team chose CONTAM software as the main tool in the simulation model. This is a specialized software developed by the National Institute of Standards and Technology (NIST), for simulating air flow and dispersion of pollutants in closed structures such as factories, workshops, and buildings.

Specifically, the team has built 02 simulation scenarios:(1) Anhydrous ammonia gas leak from a valve on the pipeline; (2) NH3 leak from a high-pressure tank.

In the above situations, the software will rely on parameters such as temperature, humidity, wind speed, ventilation level and leakage rate to calculate and display toxic gas concentrations over time at different locations in the factory. Thanks to that, enterprises can easily identify dangerous areas, exposure levels, and gas dispersion directions – which are extremely important information for building response scenarios.

Important results from simulation

The simulation results show that many factors strongly affect the speed rate and concentration of toxic gases in the air.

1. Ambient temperature: When the ambient temperature increases from 18°C to 30°C, the diffusion rate of NH3 rises as well, causing NH3 to escape into the environment faster and spread more widely in the air, increasing the ammonia concentration in the vicinity of the leakage point.

2. Humidity: When the humidity increases from 40% to 80%, the NH3 concentration in the air also rises slightly. The reason is that NH3 easily combines with water vapor to form suspended aerosol particles, so when the humidity is high, this gas is “retained” longer at the leakage source, increasing the local concentration.

3. Wind speed: When increasing the wind speed in the factory from 0.5 m/s to 8 m/s, the NH3 concentration in the air decreases significantly – from more than 80 ppm to less than 60 ppm. This is the scientific basis for factories to redesign the ventilation system to dilute toxic gas when a leak occurs.

4. Leakage rate: At a low leak level (0.125 kg/h), the NH3 concentration is only about 80 ppm. But if the leak increases to 1 kg/h, the gas concentration can exceed 600 ppm – the level that causes suffocation, difficulty breathing and the risk of death if exposed for a long time. Therefore, periodic control of the quality of valves, pipes, joints, etc., is extremely important.

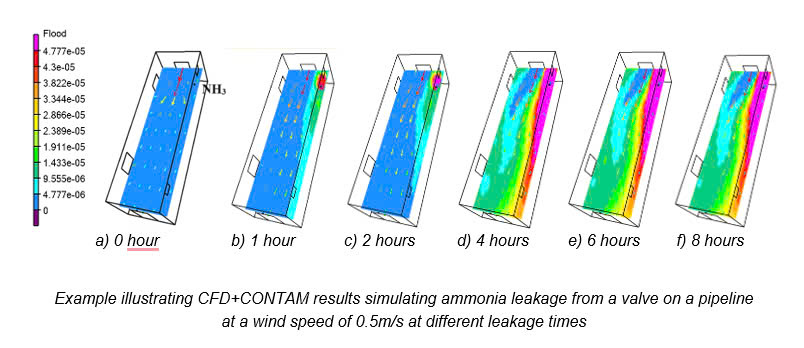

In addition to CONTAM software, the research team also combined simulation with CFD0-Editor – an aerodynamic flow modeling tool, allowing for more intuitive 3D display. This model enables managers to visualize the extent, height and density of toxic gas coverage, which can be leveraged to improve the design of warning systems and emergency exits within a facility.

Recommendations from the research

From the simulation results, the research team proposed a number of practical recommendations to improve the effectiveness of risk management and ensure safety in the working environment.

For enterprises, applying simulation models in periodic risk assessments will help detect potential risks early, thereby planning to improve ventilation systems and install NH3 gas warning sensors in areas with high risk of leakage. In addition, organizing incident response drills based on specific simulation scenarios will help improve the situation handling skills of safety officers and workers.

For management agencies, it is necessary to develop technical guidelines on the application of simulation software in chemical risk assessment, thereby creating a legal framework and professional standards for enterprises. In addition, organizing simulation software training courses for technical staff is necessary to improve professional capacity and effectively deploy models. In particular, supporting small enterprises in adopting appropriate models for their scale will help expand the scope of technology application and improve safety levels across the industry.

Conclusion

Ammonia is an indispensable chemical in many industries, but it is also a potential danger if a leak occurs. Simulation research on the dispersion of NH3 gas using CONTAM software has provided clear scientific evidence, helping to see invisible risks – thereby proactively preventing instead of passively responding.

The application of simulation technology not only contributes to improving occupational safety but also creates an important step forward in modernizing the assessment and management of chemical risks in the workplace. In the future, combining CONTAM with new technologies such as AI to analyze big data from simulations, or integrating with real-time monitoring systems, promises to bring further advances in the field of occupational safety and chemical incident response.

Nguyen Khanh Huyen

Occupational Safety Center, VNNIOSH