Research on equipment kits of emergency evacuation for workers living and working in the high building

With the rapid development of the economy, the population in large cities increased rapidly due to the concentration of economic hubs, industrial zones and demands enjoying benefits and utilities of workers. To address the surge in housing and offices, Vietnam and other places in the world have massively built high-rise residential and office buildings. The construction of high-rise buildings presents numerous benefits, except for one thing: safety in case of fire incidents. Although buildings have evacuation plans in accordance with the design but in reality these plans are insufficient. Even overseas, catastrophic events in recent years have shown the skyscrapers filled with death threats, the life-line exits in the buildings are not efficient and capable enough when disasters like fire, natural disasters or earthquakes happen.

For more options of exit for people living and working in high-rise buildings, some countries have conducted studies of individual evacuation kits. In Vietnam, the Occupational Safety Centre under the National Institute of Labour Protection has conducted research on equipment kits of emergency evacuation for employees living and working in high-rise buildings in order to help them escape when fire and explosion incidents occur.

Research equipment kits of emergency evacuation conducted by the National Institute of Labour Protection includes:

- Personal sliding device including slide-down device; sliding rope; connection ring; safety belt; auxiliary line.

- Hammer: Used for breaking doors and latching.

- Dust masks.

- Protective eyeglasses.

- Protective work gloves.

- Document guidelines for escape.

- In addition, employees could equip themselves with emergency masks and helmets.

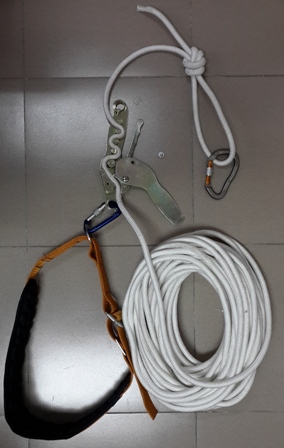

Personal sliding device:

Personal sliding device is the main component of the escape support equipment kits, including:

– Sliding rope: synthetic fiber rope of 12mm diameter, polyester fiber core (PET), polyamide fiber sheath (PA).

– Hand brake: made from SM400C Japanese steel by punching method.

– Abdominal belt: using abdominal rope of safety belt against falling from high.

– Connection ring: using high quality imported connection rings.

Details have been fabricated, assembled and quality controled to meet the requirements of standard EN 341, related technical documents and requirements of actual use.

Figure 1: Personal sliding device

Table 1: Technical requirements of personal sliding device

|

No |

Details/ Criteria |

Materials, specifications |

Technical requirements of EN 341 (Devices of D group) |

Technical requirements for personal sliding device |

|

1 |

Sliding rope |

– Synthetic fiber – Diameter: 10 to 13mm |

– Static Durability: 5 kN – Elongation: <8% when using |

– Static Durability: 12 kN – Elongation: <8% when using |

|

2 |

Hand clamp squeezing force |

– Right hand squeezing force <120N with 80 kg testing object |

– Right hand squeezing force <120N with 80 kg testing object |

|

|

3 |

Sliding down speed |

– Speed ≤ 2 m/s |

– Speed ≤ 2 m/s |

|

|

4 |

Sliding down energy |

Testing object: 100 kg |

– Number of attempts: 1 – Temperature ≤ 48oC |

– Number of attempts: 34 – Temperature ≤ 48oC |

|

5 |

Function |

Testing object: 100 kg |

– No damage causing unsafety |

– No damage causing unsafety |

Assessment of personal sliding device quality

Standard EN 341: 2011 has been used as a basis for evaluating and assessed quality results of devices are as follows:

Table 2: Evaluation results for personal sliding device

|

No |

Details/ Criteria |

Materials, specifications |

Technical requirements for personal sliding device |

Evaluation results |

Conclu-sion |

|

1 |

Sliding rope |

– Synthetic fiber – Diameter: 10 to 13mm |

– Static Durability: 12 kN – Elongation: <8% when using |

Static Durability: >12 kN Elongation: <6% when using |

Pass |

|

2 |

Connection ring |

Cast aluminum |

No damage when trying to pull (≥ 15 kN/3min) |

No damage |

Pass |

|

3 |

Abdominal rope and lock |

No damage when trying to pull (≥ 8 kN/3min) |

No damage |

Pass |

|

|

4 |

Ring D |

Steel |

No damage when trying to pull (≥ 12 kN/3min) |

No damage |

Pass |

|

5 |

Reliability of splice at end of sliding rope |

No slip while testing (≥ 12 kN/3min) |

Not slipped |

Pass |

|

|

6 |

Hand clamp squeezing force |

Squeezing force Fb <120N with 80 kg testing object |

Fb<80 N |

||

|

7 |

Sliding down speed |

Speed Vt≤ 2 m/s |

Vt≤ 2 m/s |

||

|

8 |

Sliding down energy |

Testing object: 100 kg |

– Number of attempts: 34 – Temperature ≤ 48oC |

– Number of attempts: 1 – Temperature ≤ 48oC |

|

|

9 |

Function |

Testing object: 100 kg |

– No damage causing unsafety |

– No damage causing unsafety |

On-situ testing personal sliding device

Because the nature of this type of device is used only for emergency situations, therefore in order to confirm reliability, as well as to test the operability of the device for the purpose of completing more products, the researchers have directly tested the device on field and confirmed that personal sliding devices have worked fine.

Enclosed with the escape support device kits is the booklet “Guidelines for a fire escape in high-rise buildings”. This document consists of 2 parts:

- Part 1: Manual for use and maintenance of escape support device kits

Part 2: A guidance for emergency exit in case of fire in high-rise buildings.

|

|

|

|

Figure 2: Details of one escape support device kit |

Figure 3: Sliding down with personal sliding device |

The device different from other foreign existing devices is that it could be used to drop people down while foreign device is able to slide – down. The kit is compact: the total mass of kit is 8 kg (with 50 m of sliding rope) .

Sliding devices are made from Japanese high quality steel and are galvanized to ensure anticorrosion with long term storage under tropical conditions, hot and humit.

This product can be used for the jobs as painting or glass cleaning for high buildings. It could be used both as a sliding down device and safety equipment.

REFERENCE

- Kieu Ngoc Hanh (1980), Project report: Technical requirements and evaluation method and using methods for safety belts (TB12), National Institute of Labour Protection.

- Le Duc Thien et al., Project report 200-6/VBH, Research to develop a durability rating system of safety belts.

- Le Duc Thien et al., Final report of scientific task coded NVKHCN-VBH 203-3, Testing fabrication of some personal protective equipment having special functions for workers exploit ting bird’s nests.

- Le Cong Duong chief author (1997), Materials Science, Science and Technology Publishing House, Hanoi.

- Nguyen Huu Nieu; Vinh Tran Dieu (2004), Physical chemistry of polymers, National University Publishing House, Ho Chi Minh City.

- TCVN 7802-1 to 6: Personal fall-arrest systems

- EN 341:2011: Personal protective equipment against falls from height – Descended devices.

- EN 1497: Rescue equipment – rescue harnesses

- EN 364:1992: Personal protective equipment against fall from a height – Test methods.

- Christian Dalloz Holding Deutschland GmBH & Co. KG, Descended device AG10 – Instruction for use

- Anthron, Descender Instruction Manual – EN

- CMC MPD User Manual

- European patent application; Application number 88307145.8

- Noworries_descender catalogue

- United state patent: Device for lowering a person or a load on a rope ; Patent number: 4,580,658; Date: 8/4/1986

- United state patent application publication: Descent control device; Publication number: 2003/0051944 A1; Date:20/3/2003

- http://www.lifedescent.com.au/ Lifeline Descent, a new level of safety for emergency high rise escape.

- http://www.cmcrescue.com/category.php?dept_id=2 Rescue Kits

(Nguồn tin: vnniosh.vn)