Research on assessment of work safety using mechanical – electrical equipment for agriculture in the southern provinces, and propose some solutions to minimizing working accidents

PhD. Nguyen Dac Hien

Sub-institute of Labour and Environment Protection in Southern Vietnam

I. BACKGROUND

Occupational safety and health (OSH) issue in agriculture has been long discussed and in recent years by the State and other relevant departments, especially when agriculture makes considerable contribution to the country development, it has received more attention of appropriate authorities and social organizations. However, this attention was insufficient in OSH work for employees in the agricultural sector. Safety risks when using the machinery has not been mitigated, harmful factors in this field are still evident.

There are many reasons for the increase of occupational accidents in agriculture, but the main reason being that farmers still lack understanding of OSH and awareness of respecting OSH regulations. On the other hand, most farmers are now filling the knowledge and skill gap in using agricultural machinery, using a “vocation trains vocation” manner, so the occurrence of accidents was unavoidable.

OSH issue in agriculture could not be resolved overnight, but it needs proper care of State management agencies at all levels, professional organizations, agencies and appropriate authorities from central to local levels to gradually enhance OSH knowledge for workers in this field.

II. OBJECTIVES AND CONTENTS OF STUDY

2.1. Study objectives

– To evaluate the work safety situation in the use of mechanical – electrical equipment in agricultural production in the Southern provinces.

– To propose some feasible solutions to reducing working accidents in agriculture in the Southern provinces.

2.2. Study contents

– To overview the situation of actual use of mechanical – electrical machinery, equipment, tools in production and for production in some common industries in the Southern provinces.

– To identify hazards and risks from using machinery in the Southern provinces.

– To survey and assess the situation of working accidents due to mechanic – electric agricultural machinery in production, to analyze the cause of accident (the parameters and criteria for safety, safe structure, qualifications and skills of users, etc.).

– To propose some managerial and techniques solutions in order to ensure safety and reduce working accidents for users of mechanic – electric agricultural machinery.

III. STUDY RESULTS

3.1. Identification of dangers:

The comparison of dangers occuring during the use of mechanical – electrical equipment in reality with safety standards for some machine as cited suggests that there is still a relatively large distance between application of standards and actual use of machinery .

Learning from the survey, we have discovered that: There are dangers from the equipment itself (blades of mowers, blades of rowing harvesters, etc.). Reduction of puncture and cut risks entirely depend on the level of safe work understanding and practice of employees for each device.

3.2. Survey results:

Conducting a survey on 526 agricultural producing households that use mechanical – electrical equipment in agricultural production, we have totaled up the types of machines used by each household and the common forms of accidents during the use of these types of machines; information about users in order to generally assess the current status of work safety in agricultural production in a number of stages as mentioned above.

General observations:

- The majority of equipment operators are in the working age (> 18 years), of which only 16% are professionally trained and 28% have heard (not yet trained) of occupational safety while working with machinery.

- Machinery and equipment: for mechanical devices like plough, rake, harrows tractors, harvesting – threshing combines, accidents caused by objects thrown and shot at, by being stabbed, cut and by falling maintain at high rates.

- A number of rotating parts cannot be shielded so it is difficult to control thrown and shot objects due to the rotation of working parts during operation.

- Among these mechanical devices, the open working parts are normally sharp (cutting knife and discs, milling blades, etc.) and pointed (rice cleaving spearhead, harrow teeth, etc.) so accidents by being crashed and cut have high rates.

- Accidents caused by falls: there are many different causes. In normal operation, accidents could happen when drivers cannot control the machine (with two- wheels plows and tillers). Falling should occur due to slipping when climbing up or down tractor, or by concentrating too much on productivity and neglecting work safety (persons giving a hand with the gathering rice on harvesting – threshing combines, etc).

- Water pumps: Water pumps of producers are usually electric pumps. Major accidents here were electric shock and falling. Pumps used are not fixed but would move as requirements of cultivation and crops, therefore the shell of the wire insulation is easily damaged by movement in unfavorable working environment. Falls due to slippery work surface could also lead to accidents.

- Pesticide spraying devices: Hazards come from pesticide splashing and poisoning during spraying. Falls also have a high rate because workers often have to carry heavy equipment and by paying attention to spray they may forget to observe the ground and often stumble.

3.3. Discussion

We have chosen a narrow issue, only to assess the status of labour safety during the use of mechanic – electric agricultural equipment for rice production in paddy soil preparation, caring and harvesting in five provinces in South East region and Mekong Delta by surveying 526 agricultural producing households that use mechanical – electrical machinery including 13 types of device and a total of 1,064 devices. Information collected includes: Information about operators controlling devices (age, vocational training, knowledge of safety); causes of occupational accidents.

By analyzing of the survey data, we found out the 3 groups of cause that are the main factors leading to occupational accidents:

1. Human factor:

The issues related to workers controlling machinery: health, skills (proficiency, understanding of using machinery), vocational age, knowledge of occupational safety in use of machinery.

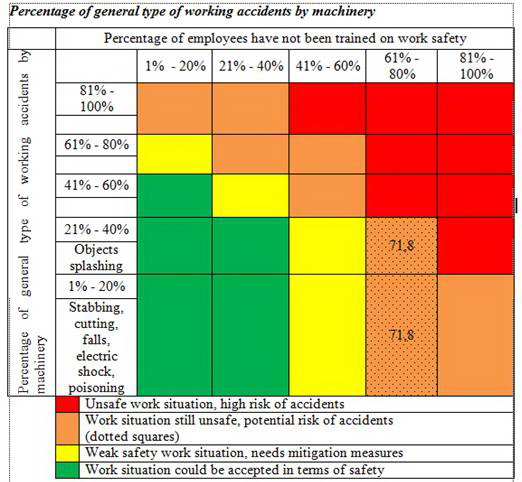

We have chosen two parameters to assess potential occupational accidents in the use of machinery and equipment:

+ The users of equipment that have understanding of safety: 28.2%

+ The users of equipment that have no understanding of safety: 71.8%

2. Machinery factor:

The study team has surveyed 526 agricultural producing households that use mechanical – electrical machinery in production and found that the common forms of accidents when using machines include: stabbing, cutting, objects splashing, falls, electric shock, poisoning.

3. Used environment factor:

With 3 groups of cause leading to working accidents as described above, knowing the possibilities of each group can lead to working accidents, we have used the probability summation to calculate levels and ability which can lead to working accidents.

Three groups of cause can lead to working accidents independently but sometimes simultaneously by 2 or 3 causes, so if the potentiality that leads to working accidents by each of 3 causes is expressed as P1, P2 and P3, we can estimate the general potentiality leading to working accidents as Pc.

However, the study has not enough date to quantify by these parameters, so we have selected a qualitative assessment method with two-dimensional matrix on the basis of human and machinery factors; the factor of working environment has been excluded in any circumstances. Two-dimensional matrix is designed with:

+ Column of the matrix is the human factor with one representative aspect as the rate of surveyed people about work safety training when using machinery.

+ Row of matrix is the rate of general type of working accidents encountered when working with machinery.

IV. CONCLUSION AND RECOMMENDATION

Through survey and assessment of occupational safety status in the use of mechanic – electric agricultural machinery and equipment, the research team has found a number of major causes leading to accidents when using machinery and equipment for agriculture production and built some specific measures on management and technology contributing to the dissemination and application of these solutions for employees using agricultural machinery, in order to minimize working accidents in the future.

Besides, in terms of technical solutions, the research team has recommended the application of power turn-off device for equipment using single-phase electric power when leakage current happened with leakage current # 20mA. The equipment has been tested in the laboratory and has reliable operation.

This study is conducted to propose to authorities at all levels that more attention should be paid to better train agricultural workers on safe usage of machinery and equipment in order to enable them to work safely.

REFERENCES.

[1]. Tran Duc Dung editor, Curriculum on Agricultural Machinery and Equipment – Volume I; Hanoi Publishing House – 2005.

[2]. Tran Van Trinh, Final Report of study: ‘Study the protection solutions for agricultural workers and determine the viable conditions of their applications in production at Song Hau farm – Can Tho province’ – Code: 96/53/VBH/PV – 2003.

[3]. Ton That Khai, Tsuyoshi Kawakami, Training programme on safety, health and labour conditions in agriculture. ILO / JAPAN Multibilateral Programme – 2002

[4]. Ministry of Agriculture and Rural Development, Research results of Agricultural Science and Technology 2006-2007 in Mekong Delta and South East provinces. HCMC 10/2007.

[5]. Directive No.20/2004/CT-TTg dated 08/6/2004, Enhance of steering and organizing safety implementation – Occupational health in agriculture

[6]. Circular No. 46/2013/TT-BNNPTNN, Promulgation of National vocational skills for group of agricultural vocations.

[7]. National Institute of Labour Protection, Proceedings of scientific works (1971-2011). Hanoi July, 2011.

[8]. National Institute of Labour Protection, Some measures to improve the living environment and working conditions for agricultural workers Handbook, Labour Publishing House – 2003.

[9]. Labor Protection Magazine No. 12/2011, pages 51-52 and No. 8/2013, pages 47-50.

[10]. Vietnam Standards: TCVN 6818-1-2010 – Agricultural Machinery – Safety, Part 1: General Requirements (1-5).

[11]. Vietnam Standard: TCVN 6818-8-2010 – Agricultural Machinery – Safety, Part 9. (1-3).

[12]. Vietnam Standard: TCVN 6818-9-2010 – Agricultural Machinery – Safety, Part 9. (1-3).

[13]. Vietnam Standard: TCVN 6818-10-2010 – Agricultural Machinery – Safety, Part 10. Rotary shaking and raking machines.

[14]. Vietnam Standard: TCVN 6818-5-2010 – Agricultural Machinery – Safety, Part 5. Tilling machines driven by the engine.

[15]. Vietnam Standard: TCVN 9195: 2012 – Agricultural Machinery – Shielding for power transmission moving parts – Open shielding without tools.

(Source: nilp.vn)